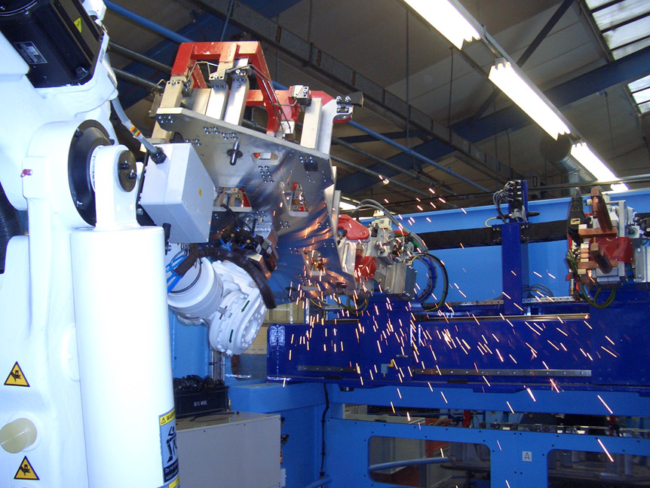

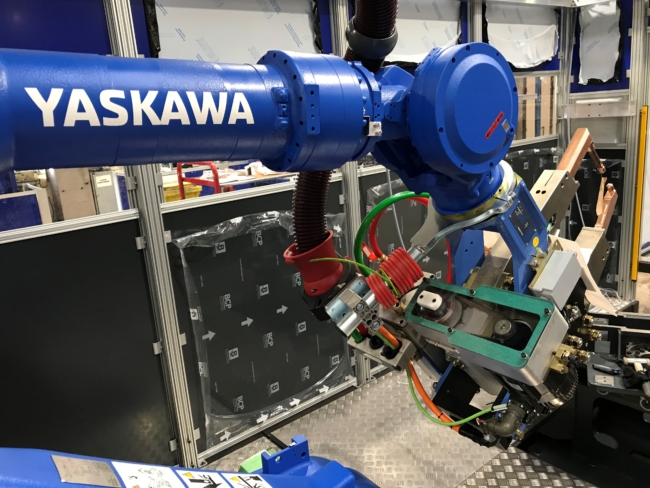

About our spot welding partnerships

Bauromat has been manufacturing automated welding solutions for most of its 23 years in operation and remains a leader for automated spot welding solutions throughout the UK. This has established strong working partnerships with some of the industries leading names and therefore resulting in solutions manufactured for household names in the automotive and general industry. Bauromat’s knowledge in the field ensures a solution of the highest quality and twinned with its partnerships with industry leaders you will also receive the support of internationally recognized brands.

Rexroth Bosch

A subsidiary of globally recognised brand Bosch, Rexroth is the conglomerate’s arm that provides quality spot welding controllers and timers. Used in around 80% of automotive manufacturers, Rexroth systems boast high flexibility, fast commissioning and optimized controls, guaranteeing quality results for the end-user.

Harmes & Wende

German supplier Harms & Wende are international suppliers of resistance welding equipment including its innovative software, PQS, of which Bauromat is an exclusive provider throughout the UK. PQS is a monitoring system that is industry 4.0 ready and allows you to easily monitor and manage every individual weld in your system. This allows for more accurate measurements and output of a higher quality.

BF Entron

Founded in the 1970s, Entron has been supplying weld controls for a range of industries since day one. From automotive to electrical, Entron has supplied to a diverse range of industries providing everything from resistance welding controls to AC and DC inverters.

Can we help you find the right Spot-Welding solution? Contact us below...

Spot Welding FAQ's

Spot welding robots work using a series of servo motors which are programmed to move the robots from point to point. Once recorded, the robot can seamlessly run through the movements. The spot welding robot is also in control of the spot welding gun.

By automating your spot welding process you are guaranteed to increase the efficiency of your output. An automated spot welding robot can produce parts much more quickly than other means while also being consistent in its approach, making sure you get the same results each time.

As well as spot welding, all other types of welding can be automated too, these include varieties of arc welding such as MIG, TIG and laser as well as the like of friction stir spot welding.