Accuracy is key to your manufacturing process.

You might be conducting regular examinations, using the latest technology to inspect parts or even need to use elaborate camera equipment to make detailed digital replicas. Whatever process you’re using, the chances are, it can probably be more efficient.

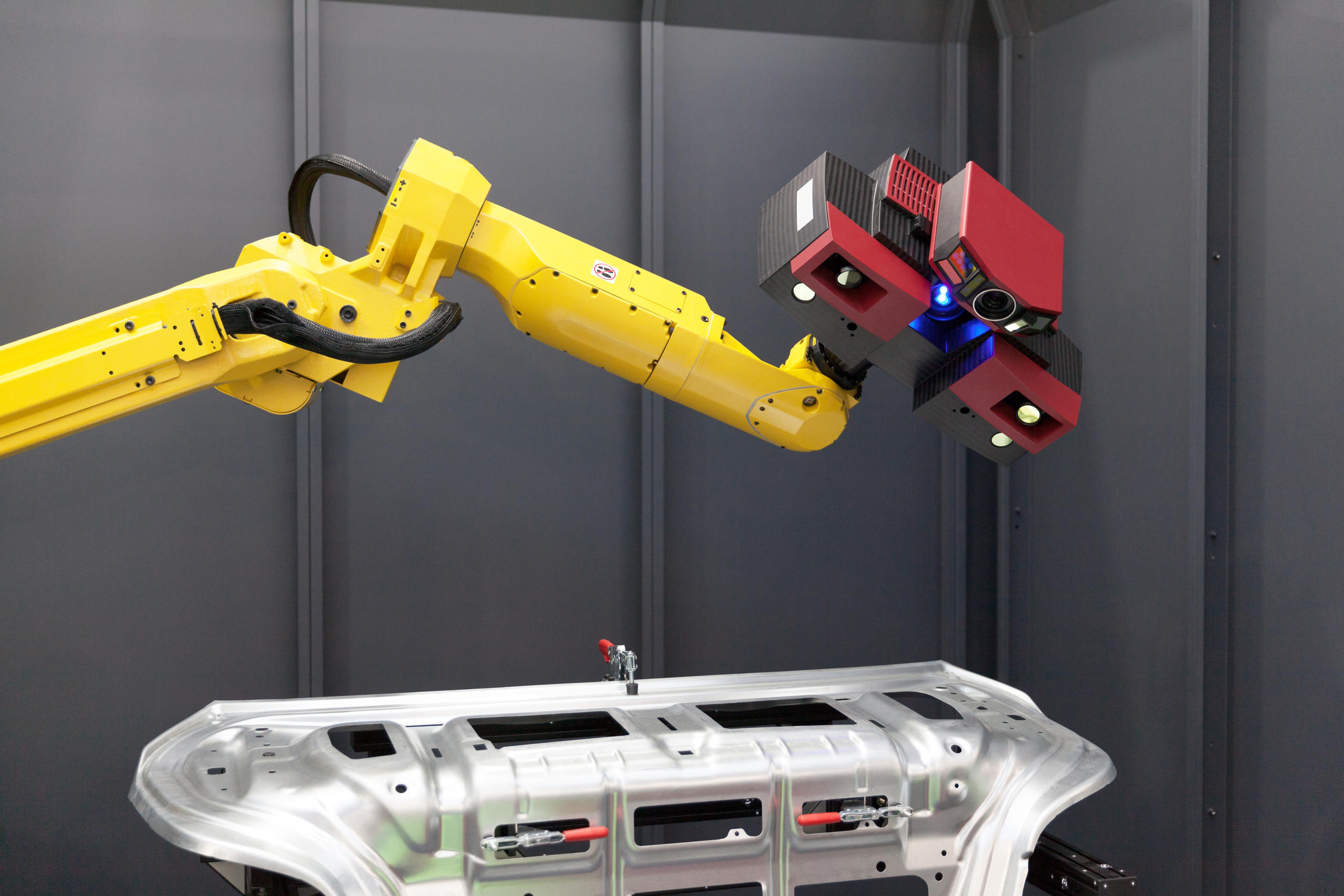

That’s where automated part inspection comes in handy. Using quality control robots and other six axis robotic arms in a complete automated system is a fantastic opportunity to streamline the manufacturing process and work to a far higher quality.

If this sounds like your current manufacturing process, you’ve probably got a lot of questions. Luckily we’ve answered some of the most frequently asked ones surrounding automated part inspection.

Inspect it…

Usually featuring a vision system, inspection automation solutions can refer to a variety of things. These range from part orientation to quantity checking, or even quality control and can ensure a higher number of parts are inspected, and at a more consistent level. Inspection systems can also work alongside a variety of automated finishing solutions to ensure a smooth manufacturing process, from start to finish.

...and Finish It.

Product finishing processes can refer to a variety of applications, from polishing and deburring to laser marking and labelling, finishing is the final step in the parts manufacturing process and can be integrated into existing lines, or manufactured with an inspection system.

Can Robots Be Used Quality Control?

Introducing a quality control robot can instantly help you increase your overall efficiency; incredibly diverse, one task robots can be programmed for is quality control.

It’s important to note however, that an industrial robot alone can’t be used for quality control and you need to specify the surrounding equipment for the robot to be able to do this.

For instance, when it comes to part inspection for manufacturers, you may need to acquire things such as cameras or 3D scanning equipment. Programmed into the automation system’s PLC, the robot can then be used for quality control.

Talk with your automation provider to understand the requirements for you.

What Are The Advantages of Part Inspection Robot?

Like with all manufacturing processes, the use of a robot, in this case a part inspection robot, is advantageous across the whole board.

From speeding up the process so your business makes more parts each, to ensuring higher levels of quality, more consistently throughout. If your part inspection robot is part of a fully optimised automation system, the skies the limit.

The important thing to do is discuss your targets prior to the manufacture of any system, only with this approach will you truly have a system that brings all of the discussed advantages.

Are Part Inspection Robots More Efficient?

When compared with the manual process, there is no comparison. Part inspection robots are far more efficient and can guarantee high levels of quality, eliminating any chance of human error.

Like all forms of automation, it’s about setting your targets and having the automation system, part inspection or otherwise, designed to meet them.

What Sort of Part Inspection Solutions Are There?

Depending on your manufacturing requirements, your part inspection robot solution can vary. If you need to monitor the volume of parts produced you might require a simple solution with a fixed camera.

Likewise, if you need to assess the quality of parts manufactured, the system may need to be more elaborate. Multiple part inspection robots may be needed and additional 3D scanners or even X-Ray machines depending on the part’s preferred tolerances.

Understanding the manufacturing process that you are trying to achieve is the best way of understanding the type of part inspection solution that you need.

One Application or Many

Although automated part inspection and finishing go hand in hand as an ideal robotic solution, the decision is entirely up to the customer. You might already have an inspection solution in place and require automation to help give a quality finish to the part, or you might need automation to be able to inspect your part before moving onto an already proven finishing process.

Whether it’s part orientation, quality control or quantity monitoring, all inspection possibilities are available through Bauromat. And likewise, for deburring, polishing, or labelling, if something requires a finishing touch, automation solutions are a guaranteed method for greater results.

Whatever levels of automation you need, Bauromat can design and manufacture a system entirely for the requirements of the customer, with a philosophy of ‘integration from day one. This means that we’ll listen to all customer requirements and ensure that at all stages of the design and manufacture they are part of the conversation, resulting in a solution of the highest quality. Only through this process do both parties get the best results, solutions that are far greater than the concepts.

BAURO-MATE

Bauromat’s flexible automation solution, BAURO-MATE is an ideal solution for a range of applications including part inspection and finishing. Designed in two halves, separating the robot from the application, BAURO-MATE allows for complete process flexibility. If the customer has existing finishing or inspection equipment, all they’ll require is the BAURO-MATE robot half to be simply and cost-effectively integrated into existing production lines. Likewise, if the whole process needs automation, BAURO-MATE can be designed and manufactured for any and all of the customer’s requirements.

Find out more about BAURO-MATE here.

Can Part Inspection Reduce Errors In Manufacturing?

The simple answer is yes. Human error is incredibly common when it comes to part inspection in manufacturing. Having a robot system that is programmed to repeat the same tasks over and over, without fail is the single best and most efficient way to reduce any human error.

You can find out more about reducing errors in the manufacturing process through the introduction of automation by speaking to your automation partner.

Is Part Inspection & Finishing right for you? Contact us...

Part Inspection & Finishing FAQ's

A machine vision system is a robotic automation solution that uses cameras and scanners that help the machines within visualise the surrounding area and find parts to collect.

Machine vision systems use cameras and scanners that, when programmed into the robot's software can paint a picture of the environment and ensure that the machine deals with parts correctly.

A robot vision system is an automation solution that uses a camera and/or scanner that when programmed into the robot's software, allows the robot to visualise objects. This is useful for parts that must be picked up in a particular way.