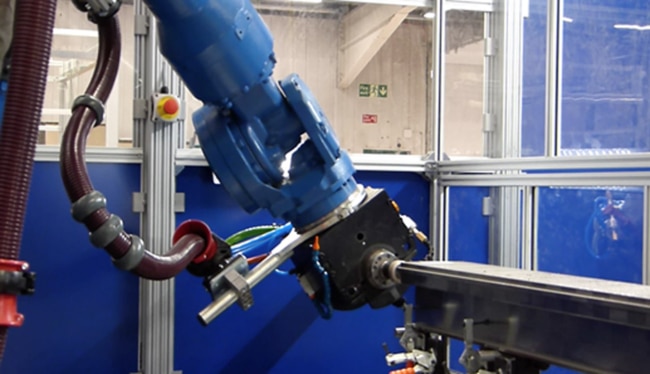

Drill, Cut, Grind

Cutting, chopping, drilling, tapping, grinding; the list goes on. Whatever machining process is required to create your finished product, or form a part for a larger manufacturing process there is a Bauromt manufactured solution for you.

With experience in a range of machining solutions, from heavy industry drilling to product prototyping, end users are safe in the knowledge that every aspect of the Bauromat automated solution will be

Bespoke Solutions,

Concepts To Work For You

Bauromat prides itself on solutions that are better than concepts, straying from the term ‘standard’ as in automation, no two solutions are ever going to be the same. Despite this, Bauromat ensures the correct solution will be found. Using our standard concepts used in various other applications (see BAURO-Arc for more) the basic design can be adapted to suit machining specific applications, whatever the scale or part requirements.

If your requirements can’t be fit into a standard concept, then Bauromat has the capability to create entirely bespoke systems with a dedicated team of in-house designers and engineers for every automation possibility.

Integration from day one

With a philosophy of integration from day one, Bauromat’s automated solutions give greater results than the concepts suggest. From day one, Bauromat works closely with the customer and its parts to ensure that the automated solution ticks all the boxes and is guaranteed to give higher levels of consistency and quality. Customers are given access to a unique project management system that enables them to see everything from meeting minutes to the list of who’s working on what and when.

You can read more about our philosophy and approach to automation here.

Let’s find the best machining & cutting solution for you...

Machining, Cutting, & Finishing FAQ's

Depending on the size and scale of the material being cut ultimately decides what robot to use. Typically you should consider a mid-sized industrial robot, although this can be discussed with your robotic solutions provider.

Like all processes, industrial robots help improve the quality, efficiency and consistency of your machining process.

Like all industrial robots, on average they should last around 15 years. however, this does depend on things such as the availability of spare components, software updates and the working environment.