Let our Concepts be Your Solution

The BAURO-Arc family are concepts as opposed to standards because we know that no two robotic arc welding solutions are the same. Our concepts allow each system to be tailor-made to the customer, whether adding space for additional robots, more industry 4.0 technology, different types of user access or simply different colour system guarding. The customer and their part is the most important thing, and our Arc solutions allow that to be the case.

Position, Plug-in, Play

All BAURO-Arc systems are manufactured on a steel base with multiple access points for forklift trucks. This means that your BAURO-Arc solution can be easily positioned and manoeuvred in place. What’s more, as the systems are shipped as a complete unit, minimal time is lost as there is no need to re-assemble on-site, it’s as simple as connecting the power and away you go.

Which Solution is Right for me?

We’re not expecting the customer to know exactly what system they need and with what additions, let us talk closely with you and come to the decision together. The most important thing at the initial stages is your part and required volumes. From this, we work out how much welding is needed on the part, what sort of manipulation will be required to assist the robot, and how many parts you will need per cycle. This enables us to narrow down a concept, and from that customise it to suit your specific requirements.

Meet the BAURO-Arc Family...

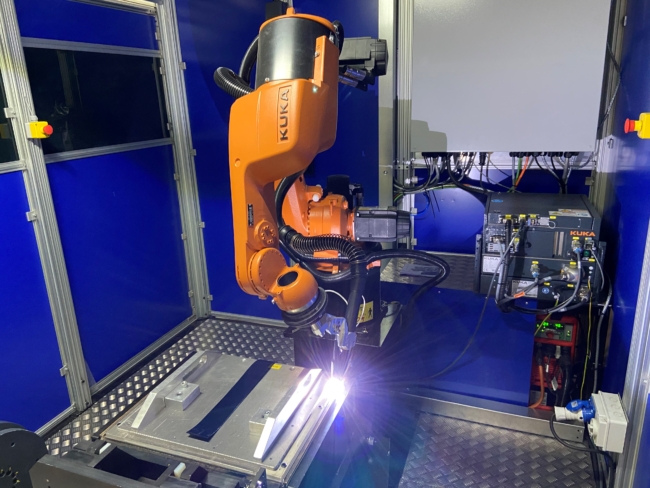

BAURO-Arc Compact

The BAURO-Arc Compact is the smallest concept among the Arc family with a footprint of just 4.4m2 it’s the ideal solution when space is at a premium. With a fixed table, the system can also feature a manual (Compact M) or powered (Compact P) turntable, suitable for a variety of tasks. The BAURO-Arc Compact is the ideal, low-cost solution, with prices starting as low as £45,000 or £29/day.

BAURO-Arc 300

The BAURO-Arc 300 family of arc welding solutions features a ‘Ferris wheel’ turntable. While allowing twice the output with two sides, the Ferris wheel can also allow for further part manipulation. In synchronisation with the robot, it’s the ideal solution for cylindrical parts or parts that require highly accurate welds.

BAURO-Arc 500

With a head, a tailstock that can be positioned as far apart as the part dictates, the BAURO-Arc 500 is the ideal solution for rounded parts that require additional manipulation. Due to its single side design, the system is better suited to parts that are at a lower volume but require a higher and more accurate quality of the weld.

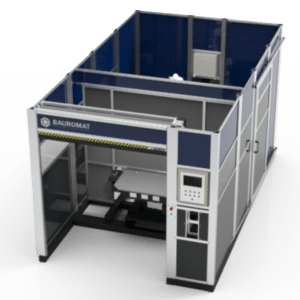

BAURO-Arc 200

BAURO-Arc 200 is our most diverse range of arc welding solutions. With 3 variations: a manual (200M), powered (200P) or servo-driven (200TS) turntables, the BAURO-Arc 200 family allows for double your current efficiency as a minimum. Each turntable features two stations meaning parts of up to 500kg a side can be loaded and unloaded while the robot welds the other side.

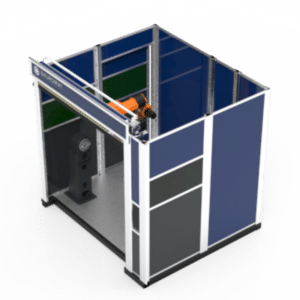

BAURO-Arc 400

Featuring a robot mounted at the centre of the turntable and above the part, the BAURO-Arc 400 focuses on ultimate flexibility. The robot’s positioning opens up the working envelope to a higher level when compared with other systems.

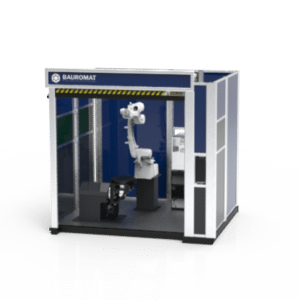

BAURO-Arc 800

BAURO-Arc 800 features a tilt & turn manipulator, which when synchronized with the robot provides greater part manipulation and therefore more weld possibilities. With payloads of up to 1 tonne depending on the manipulator model, this arc solution is ideal for low volume production.

Bauro-Arc Breakdown

| Name | Description | Cost | Ideal For |

|---|---|---|---|

| Bauro-Arc Compact | BAURO-Arc compact is Bauromat's smallest welding system and is the ideal introduction to automation. With a footprint starting from just 4.4m2, BAURO-Arc Compact includes everything needed to start your automation endeavour and can be a valuable training tool. | Starting from £45,000 | - Part prototyping - Small sized, low volume parts - Automation training - Schools & Universities |

| BAURO-Arc 200M | With a two-station manual/semi-automatic turntable, BAURO-Arc 200 M is the smallest and most cost-effective welding system in the BAURO-Arc 200 family. Designed to maintain the BAURO-Arc Compact's small footprint, the 200M is a great way to quickly increase efficiency. | Starting From £50,000 | - Sporadic volumes - Small/medium batch sizes - Automation training |

| BAURO-Arc 200P | The BAURO-Arc 200P features an automatic turntable controlled via an external servo axis. Programmed as part of the whole system, when running at fully capacity, the powered turntable option allows for greater efficiency | Starting From £65,000 | - High volumes - Small sized automotive assemblies |

| BAURO-Arc 200TS | The largest of the BAURO-Arc 200 family, the BAURO-Arc 200TS provides a servo-driven two-station positioner with additional axes for 180O part indexing making it the perfect solution for large parts that require welding on both sides. | Price On Request | - High volumes - Large industrial assemblies - Welding required on both sides. |

| BAURO-Arc 300 | The Bauromat BAURO-Arc 300 cell is an automated welding system based around a two-station indexing ferris wheel turntable that manipulates the product for the robot to weld. | Price On Request | - Cylindrical parts - Pipes & tubing assemblies -Long assemblies with welding on both sides - Larger industrial assemblies |

| BAURO-Arc 400 | Boasting a smaller footprint than traditional 1,000kg systems, the BAURO-Arc 400 is designed around a centre mounting turntable, creating a greater working envelope without losing valuable floor space. | Price On Request | - High volumes - Large, complex industrial & automotive assemblies - Welding required on both sides - Large volume of welding (additional robots available on floor and positioner) |

| BAURO-Arc 500 | Easily scaled up to feature multiple stations, the BAURO-Arc 500 is a welding system that features a Head & Tail stock manipulator with coordinated motion. Its small footprint makes it ideal for smaller workshops | Starting From £70,000 | -Cylindrical parts -360o welds - Pipes & tubing assemblies - Welding both sides of a component |

| BAURO-Arc 800 | Easily scaled up or down depending on the size of the required positioner, the BAURO-Arc 800 system is a flexible solution featuring a tilt & turn manipulator. With options for small footprints, the BAURO-Arc 800 can include positioners capable of up to 20 tonnes. | Price On Request | -Box type applications - Exhaust welding -Large and small applications |

Bauro-Arc Welding Systems

Is BAURO-Arc the right match for you? Contact us today...

BAURO-Arc FAQ's

BAURO-Arc welding solutions offer a variety of automation concepts that can be tailor-made to suit specific requirements. This is a more cost-effective alternative to other arc welding robot systems as less time and cost is spent on bespoke design.

BAURO-Arc welding systems are available in a range of concepts to suit a variety of customer needs. Bauromat can help you narrow down the right system for you following initial conversations about your project.

Finance is available on all BAURO-Arc systems via an external financing company. Manufacturing grants on new technologies and equipment are also available and are a great way to reduce tax bills. Contact us for more.